Problems Getting Heat Transfer Vinyl To Adhere? Try These Tricks!

Heat transfer vinyl is such a versatile material. You can apply it to most any fabric as well as wood and glass. If you’re new to heat transfer vinyl and find yourself intimidated by it, start by reading our complete guide to htv then come back here for our best tips on getting heat transfer vinyl to adhere.

Tip Number One: Prewash

When you’re working with wearables like t-shirts, onesies or even tote bags, it’s always best to prewash those items before applying heat transfer vinyl. Fabrics tend to shrink when washed and dried and if the shrinking occurs after you’ve applied the heat transfer vinyl, you could end up with wrinkled and/or peeling designs.

Tip Number Two: Preheat

Preheating your wearable or fabric items ensures a a strong bond and helps to remove any wrinkles that could cause the design to have creases. Use an iron to warm the area where you plan to place the decal for several seconds beforehand. If you’re using a heat press, press the blank item for a few seconds to heat the fabric.

Tip Number Three: Heat Settings

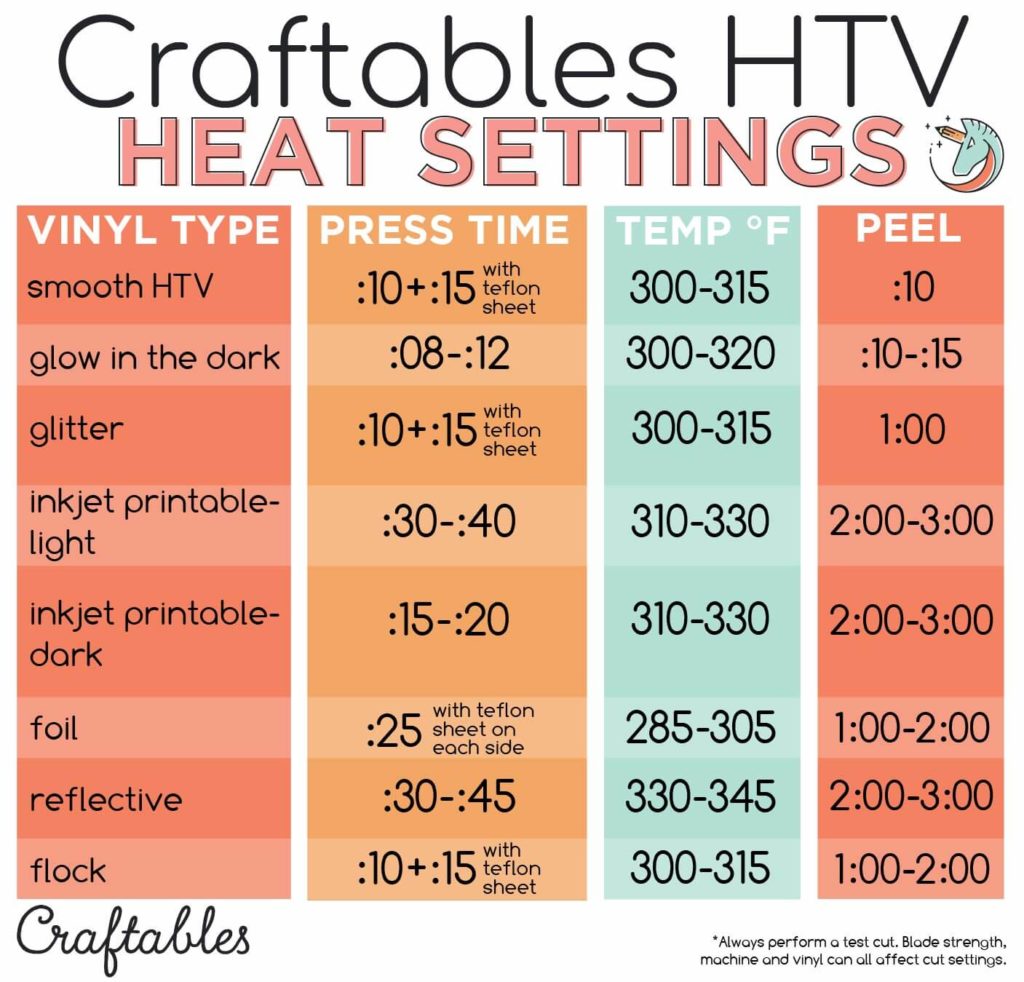

Setting the correct temperature on your iron or heat press is a crucial part of the heat transfer process. If the temperature is to low, the heat transfer vinyl won’t bond. If the temperature is to high, you’ll end up burning or melting the heat transfer vinyl.

If you’re using an iron without temperature settings, choose the cotton or linen setting with no steam.

Here’s a handy heat settings chart for Craftables heat transfer vinyl:

*If you’re using another brand of htv, be sure to check the recommended heat settings for that particular brand.

Tip Number Four: Pressure

If you followed all of the tips thus far and the heat transfer vinyl still isn’t sticking, it might be the amount of pressure you’re using. This can be tricky with an iron since all of the pressure has to be applied by hand, but it is possible. Just make sure you’re working on a hard, stable surface and use the iron to press down hard over each section of the decal for at least 15 seconds.

Tip Number Five: Cold Peel

Different types of heat transfer vinyl have different instructions when it comes to hot peel vs. cold peel. I prefer to let my items cool before peeling away the carrier sheet. If you don’t have time to wait for it to fully cool, wait at least 20-30 seconds and then peel away a small corner to check. You don’t want to risk peeling off the heat transfer vinyl while it’s still hot. Give the adhesive time to cool off and bond with the fabric.

Hopefully these tips will help you succesfully create long lasting items using heat transfer vinyl. If you’re wondering what all you can apply heat transfer vinyl on, check out our What Surfaces Will HTV Stick To? post. If you have the basics down and you’re ready for the next step, check out How To Layer T-Shirt Vinyl for an easy tutorial on layering.